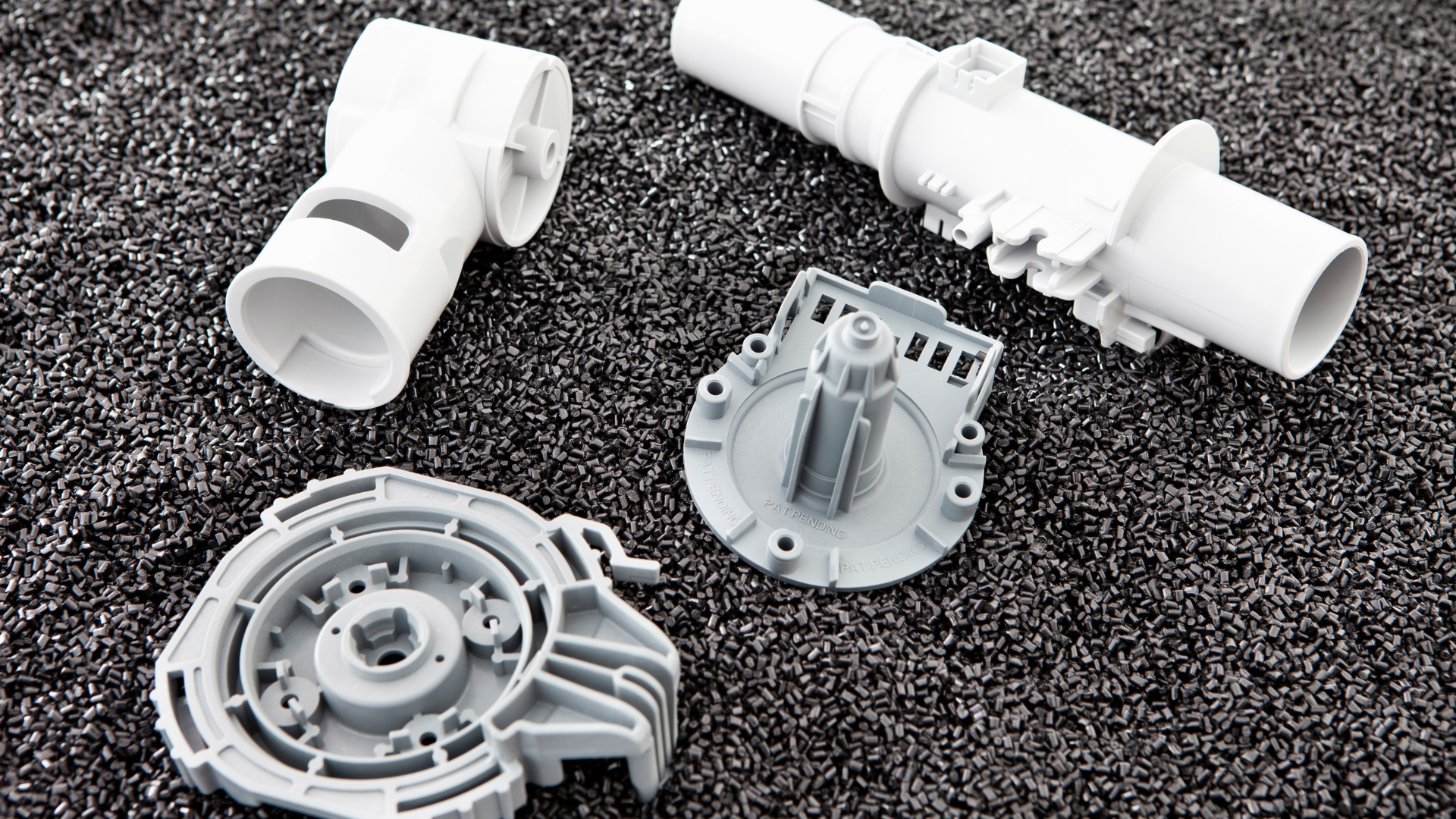

York PA Plastic Injection Molding Specialists

Specializing in small runs and low minimum orders, we are a trusted provider of plastic injection molding in York, PA, serving businesses and manufacturers in Hellam, Red Lion, East York, Dallastown, West York, Manchester, and Wrightsville. Whether you’re launching a new product, transferring existing production, or looking for expert injection molding guidance, our Central PA team works closely with you from concept to completion to ensure quality results at every stage.

YOUR PARTNER in

Custom Plastic Part Manufacturing

As a trusted provider of York, PA plastic injection molding, we offer the technical expertise and manufacturing controls required for complex and regulated applications. Our team supports every stage of production—from 3D-printed prototyping and mold development to full-scale manufacturing—while maintaining strict quality standards. With ISO cleanroom certification, we are uniquely equipped to serve medical and healthcare industries where precision, cleanliness, and compliance are critical. Choosing us for your plastic injection molding in York, PA means working with a responsive, local partner that offers faster turnaround times, hands-on collaboration, and dependable results. When it comes to York, PA plastic injection molding, we deliver the reliability and technical confidence your project demands.

From Concept to Completion

We create plastic parts for various applications and industries. We focus on serving clients in York, PA and throughout the Mid-Atlantic region. With extensive experience and production expertise, we are equipped to handle both high-volume and low-volume parts and components for a variety of industries including the following.

Medical

Delivering precision parts for medical devices and components, when ISO Certification is a must.

Military

Supporting defense and tactical applications with durable, mission-ready plastic parts for a variety of gear.

Garment

Producing high-quality plastic accessories and fasteners tailored to the garment and textile industry.

OEM / Industrial

Manufacturing custom components that meet the rigorous demands of industrial and Original Equipment Manufacturer applications.

Our Process

How it works

Concept Development & Prototyping

Every successful plastic component starts with a strong foundation. We begin with your idea—whether that’s a sketch, CAD file, or design concept—and use 3D printing and prototyping to validate form, fit, and function. This early step in plastic part manufacturing reduces risk, shortens development timelines, and ensures your design is production-ready.

Material Selection & Engineering Support

Selecting the correct plastic is critical to part performance. Our team provides expert guidance on material selection based on durability, flexibility, chemical resistance, texture, density, color, and regulatory requirements. For medical and cleanroom applications, material choice plays an even greater role in long-term performance. Through Plastic Injection Molding in York PA, we help ensure your materials align with both functional and compliance needs.

Mold Design & Tooling

Mold design is a key component of high-quality plastic part manufacturing. We develop molds ranging from simple two-plate designs to highly complex tooling systems with side-pull mechanisms, core pulls, and advanced actions. These capabilities allow us to produce intricate parts with undercuts, hollow features, and tight tolerances—while maintaining repeatability and efficiency through every York PA plastic injection molding cycle.

Molding Trials & Test Runs

Before full production begins, we perform molding trials to optimize every parameter of the process. Injection rates, pressures, and temperatures are carefully adjusted to ensure proper mold fill, accurate part weight, and elimination of defects such as sink marks or voids. Once optimized, the process is fully documented to support consistent, repeatable results in ongoing

Plastic Injection Molding in York PA.

Production Injection Molding

During production, pelletized plastic resin is melted and injected into the mold under controlled pressure. The mold remains clamped until the plastic cools and solidifies, then opens to eject the finished part. This cycle repeats efficiently, allowing

York PA plastic injection molding to deliver high-volume, precision components with exceptional consistency.

Quality Control & Final Results

Cycle time—including material loading, injection, cooling, mold opening, and part ejection—is carefully managed to maximize efficiency and control costs. As an

ISO cleanroom certified manufacturer, Susquehanna Plastic Injection Molding is equipped to meet the rigorous cleanliness, precision, and compliance standards required for medical and regulated applications—ensuring every part meets exact specifications.

Materials Expertise: Supporting Precision Plastic Part Manufacturing

Plastic Injection Molding in York PA can be tailored to meet a wide range of performance requirements depending on the material selected. Different plastics offer unique characteristics based on their chemical composition, making material selection a critical part of successful plastic part manufacturing.

Factors such as strength, flexibility, thermal performance, surface texture, density, and color all influence the final product. At Susquehanna Plastic Injection Molding, our experts work closely with you to select the ideal plastic for your application—especially for regulated industries like medical manufacturing, where consistency and cleanliness are essential. Some of our plastics include but are not limited to:

- Acrylonitrile butadiene styrene (ABS)

- Acetal

- Acrylic

- Nylon

- Polycarbonate (PC)

- Polyethylene (PE)

- Polypropylene

- Polyphenylene

- Polysulfone

- Polystyrene

- Polyurethane

Precision Tooling for Complex Part Designs

Injection molds can range from straightforward designs to highly engineered systems. Basic molds consist of two halves that separate after cooling to eject the finished part. More advanced molds incorporate features such as side-pulls and core pulls, allowing for complex geometries, internal cavities, and detailed components.

Our tooling expertise supports even the most demanding York PA plastic injection molding projects, ensuring long-term durability, consistent part quality, and reliable performance throughout the lifecycle of your plastic part manufacturing program.

A Trusted Partner in York PA Plastic Injection Molding

At Susquehanna Plastic Injection Molding, we don’t just produce parts—we build partnerships. From early-stage concepts and prototyping through molding trials and full-scale production, our team provides hands-on guidance and technical expertise at every step. With cleanroom certification and a commitment to precision, we are proud to be a trusted leader in Plastic Injection Molding in York PA and a dependable partner for high-quality plastic part manufacturing.